R&D - the driving force for production and business

With the All-in-one model, THACO INDUSTRIES provides a full package of solutions, products and services from design, processing, manufacturing, spraying, welding, painting, assembling with a variety of types from details, components, component clusters to machinery and equipment, mechanical products, spare parts, specialized equipment, etc. In the production and business ecosystem at THACO INDUSTRIES, R&D is one of the three main pillars and an important step in the All-in-one value chain. This activity is also a driving force, creating a difference in proactively proposing research and developing products, meeting international standards and specific requirements of customers.

In recent years, Thaco Industries has focused on investing, organizing research and development of products, material research and testing ... according to the production and business characteristics of each factory and unit. The Group has researched and developed a variety of products in service of fields such as: Industry (Chains, equipment for production and assembly of cars and motorcycles: welding, assembly, paint, drying, surface treatment; jig (jig), smart production management system; parts components), Agriculture (fruit packaging factory, livesty production line, banana fiber production lines) The case (solutions to transport, archive, solutions for party), seaports (smart warehouses, crane ERTG) ... helps optimize production and business activities, bringing practical effects to businesses.

Large-scale R&D center, modern technology

In early 2025, THACO INDUSTRIES inaugurated a new R&D Center on an area of 30,000 m2, with a total investment of nearly 40 million USD, including: Design Center, Materials Research and Testing Center, sample Factory and Multi-purpose Hall. The center invests in modern experimental and testing equipment systems (minimum-metal analysis equipment, trans brightness testing equipment, color measurement equipment on plastic backgrounds, fixed CMM measuring devices...) and advanced design and simulation software (NX, hyperwork, Sap2000, Tekla, E plan...).

With a team of more than 1,000 experienced experts and engineers, the Management Center focuses on R&D activities throughout the value chain from Market Research - Product Research - Materials Research - Design, simulation - sample manufacturing - Testing and product finishing.

The center focuses on researching and developing products: spare parts; lines, equipment; agricultural machinery; high-end civil furniture and products with competitive advantages. In addition to self-discovery, the center also cooperates and receives technology transfer from partners to design components, component clusters, and equipment according to specific customer requirements. In addition, the center also researched the application of metal materials (forging, high-intensity steel, alloy steel, colored metal), non-metals ( asphalt, composite, technical rubber); testing materials and components (material analysis, mechanics, endurance, working conditions, environmental impact) suitable for use, meeting quality standards, optimizing costs and costs.

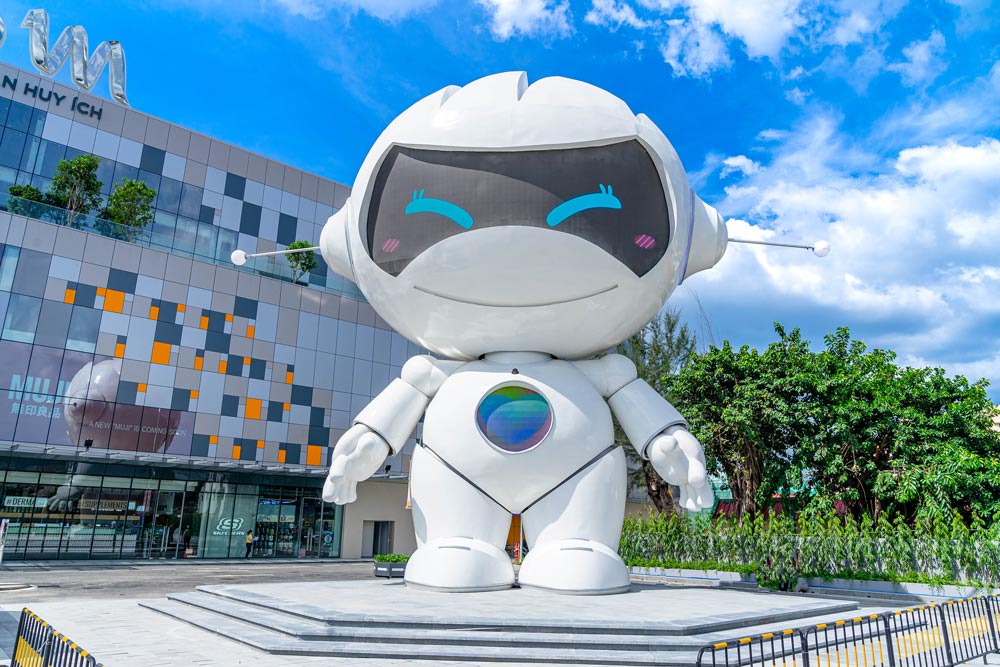

The R&D center proactively meets the requirements of customers from production lines and equipment with diverse sizes, combining many stages, technologies to small details and components with high technology content. Typical products include: banana packaging workshop (packaging capacity of 3,500 - 4,000 banana rooms/day), eRTG crane (powered by an automatic control system, load control "Active Load Control" to increase productivity and accuracy in the container unloading process), Mascot Beso mascot mascot mascot (nearly 20m high, harmoniously combining mechanical structure, automated control technology, giant LED screen system and AI artificial intelligence program to help interact with customers)...

In the coming time, THACO INDUSTRIES will focus on developing human resources, investing in modern equipment to promote research, application of new technologies, testing new materials, developing products that meet international standards, towards sustainable development, contributing to innovation and digital transformation.

During his visit and work at THACO Chu Lai Industrial Park (Quang Nam) on February 8, 2025, Prime Minister Pham Minh Chinh affirmed: "The most impressive thing that few businesses can do is the R&D Center with a large number of engineers, along with automated and digital machinery. We are very proud of THACO and believe that THACO will do a good job of pioneering innovation, promoting digital transformation, a creative economy, accelerating growth, sustainable development....