The US manufacturing sector has been in a sharp decline due to cheaper labor costs in Asia. But now, a new wave of technology is helping US factories regain that advantage of a new generation of robots, which are compact, easy to program and can work safely with humans.

According to the International Robot Federation (IFR), the US is focusing on robots with artificial intelligence, modern sensors and self-study capabilities, helping small workshops to be automated without much cost.

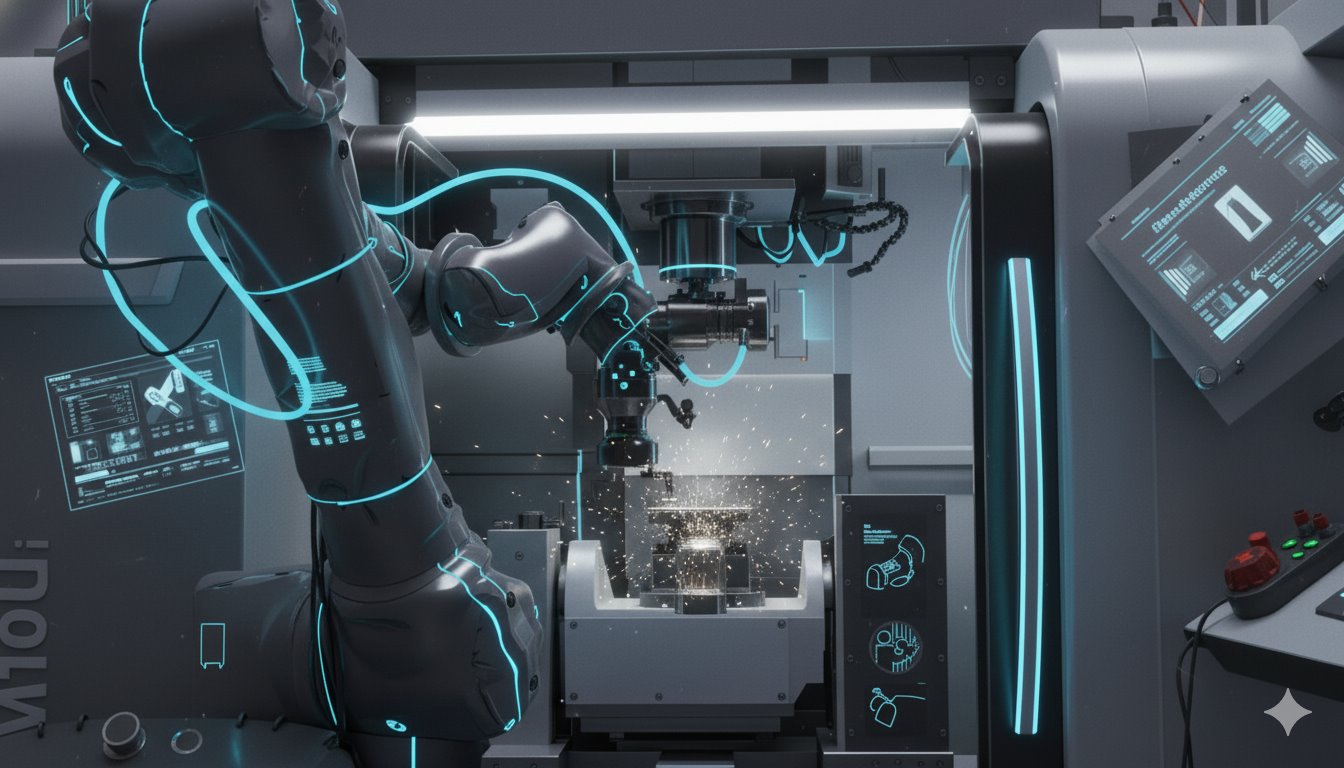

Robots such as Universal Robots' collaborative arms (cobots), Rapid Robotics or figure AI can be installed and operated in just a few hours. Previously, automation required both a team of engineers and millions of dollars, says Jordan Kauffman, engineer at Rapid Robotics. Now just a robot worth a few tens of thousands of USD is enough.

A survey by the National Association of Manufacturing Industries (NAM) shows that more than 70% of US businesses consider automation a key factor to maintain domestic production. In industrial states like Michigan and Ohio, robots are helping to solve labor shortages and keep costs stable.

Experts say that if this trend continues, the "resurgence" of the US manufacturing industry may come from the small factories - where robots and artificial intelligence are gradually changing the way people work.