The Vietnam Road Administration has just issued a document announcing the results of the inspection of the Cao Lanh - Lo Te Line Upgrade Investment Project in Dong Thap province and Can Tho city to reorganize traffic.

From September 15, 2025 to September 16, 2025, the Vietnam Road Administration (DBVN) has inspected the acceptance work during the construction process (inspecting the site and the quality and safety management records in construction) of consultants and contractors participating in the construction activities of the above project.

Regarding construction organization and quality management documents, the Vietnam National Assembly Office said that the consortium of contractors has arranged to deploy 33 construction teams, mobilizing 121 workers and 74 equipment at the construction site to carry out the construction of the remaining items.

The contractor has implemented solutions to compensate for the progress, however, the project progress is still about 0.58% behind schedule.

At the time of inspection, there were still some shortcomings in the construction work.

For contractor Truong Thanh:

Lo Te intersection: Steel materials gathered at the Lo Te intersection overpass have not been carefully covered, causing lightning; lack of a system of grille falling on the bridge at the intersections with the road below; construction of embankment, sand foundation for the N1, N2 branch road and retaining walls with the M1, M2 bridge approach roadbeds have not met the schedule; at the entrance gate of the construction site of the M2, T3 and T4 abutments, there is not enough equipment for warning signs, barriers... motorbikes serving the construction site lack traffic assurance.

Rach 2 Bridge on the left: 03 girders have been transported to the construction site but the installation is slow, the measures to anchor the girders on the beach are still sketchy.

For the contractor Nghe An Construction Company: Some locations under construction of crushed stone aggregate have the phenomenon of layering; some construction lines have not ensured the number of rolls according to the approved construction process and measures; the sand filling of the service road at some locations near the service road bridge abutment is not scientific.

For the contractor of Thang Long Bridge 7: The construction progress of the bridge deck and railings is slow, lacking construction workers at the construction site while the remaining volume is large. The construction of the bridgehead road transition is slow, depending on the progress of the roadbed construction of the road construction units.

Some bridges have installed girders, have not yet constructed level girders, measures to anchor the girders on the hood are still inadequate; steel piles waiting for the construction of wing walls, abutment top walls, bridge railings... are showing signs of rust.

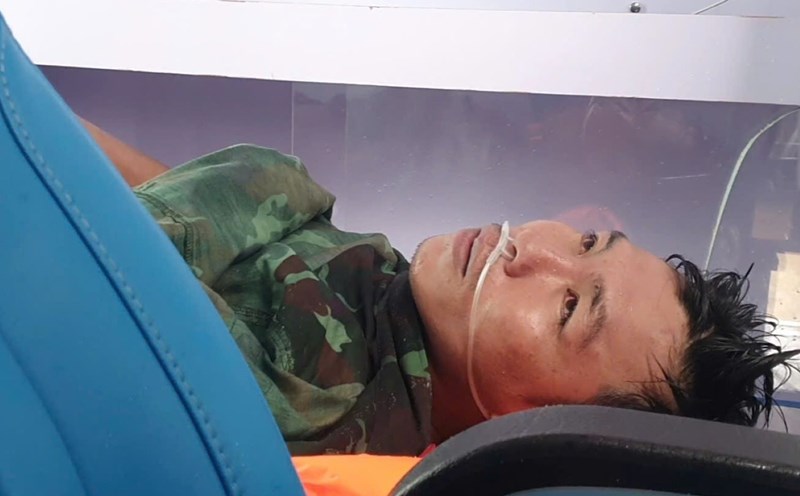

Workers are not fully equipped with labor protection equipment (safe wires, boots, etc.).

Regarding the project quality management dossier. Through the verification of the probability of the construction organization measure dossier, quality management dossier, and management dossier at the project's laboratory, there are still some shortcomings as follows:

Some documents on construction organization measures, acceptance minutes citing standards6 have expired.

Some quality management records still lack some technical documents of participating entities; some items have been constructed off site, however, at the time of inspection, no acceptance records have been provided (overpass surface, type II crushed stone joint venture, type I crushed stone joint venture...).

Some bridges have been constructed with bridge girders but have not yet provided approval documents and quality management of bridge bearings.

The construction log recorded some missing information at some construction times (ovea, number of workers, construction items, etc.). )

The production and acceptance of precast bridge girder BTCT components at factories has been implemented, however, units are requested to review quality management records, input material testing results, and quality testing during the production process to ensure compliance with the contract between units and the project's quality management process.

Regarding the laboratory system: The last-in-one nghiem station 877 carried out the experimental work for the contractor Truong Thanh at the Lo Te intersection with some contents that did not meet the requirements: narrow space, and no operation procedures for testing equipment and machinery have been suspended.

Some acceptance records for work items and testing documents of LAS-XD Laboratorate 1838 - Chau Thoi 620 Concrete Joint Stock Company in the bond quality management dossier lack the signature of the Supervisory Consultant.

The last-in-one test station -XD 677 conducts field testing for contractors (Nghe An Construction Company, Thang Long Bridge 7, Thi Son Company...): Minutes of witnessing the experimental data of concrete models lacking information on the age of concrete; Cement frequency testing form should clearly state the gas loss when burning according to which method to have a basis to compare with the required quality level corresponding to the testing method.