A team of engineers at the University of California San Diego (USA) has just developed a special fiber cooling technology that can significantly reduce the amount of heat emitted from electronic devices, helping to save energy for data centers - considered the world's leading "power-consuming machine".

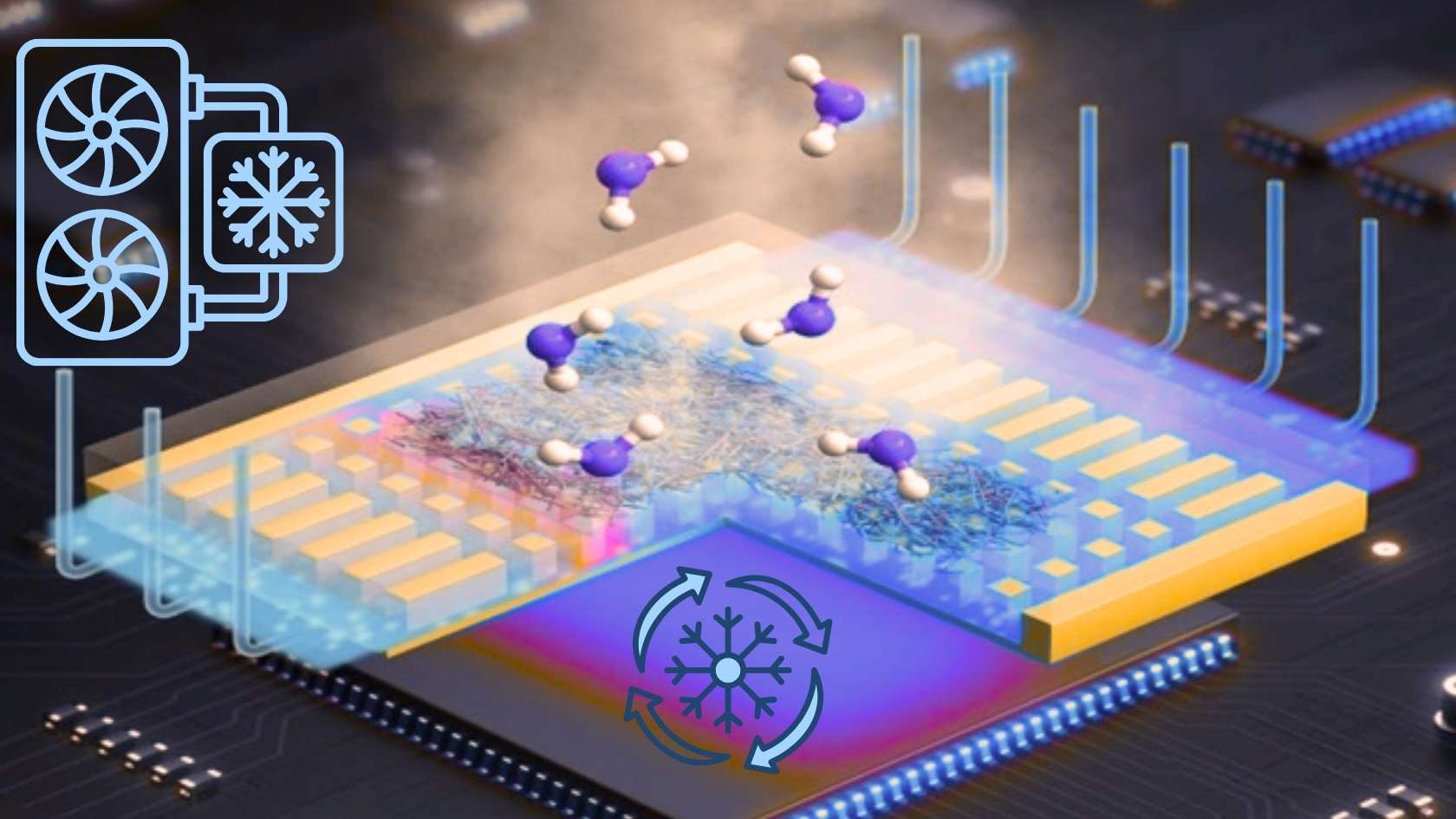

According to an article published in the journal Joule, this technology uses a layer of fiber film with a micro-structure of small bonding holes, operating according to the mao conduction principle to suck in cooling liquid and remove heat through the evaporation process. The outstanding advantage of the solution is that there is no need to use more energy during the cooling process, while helping to save water consumption compared to many traditional cooling systems such as fans, heaters or liquid pumps.

In the context of continued expansion of artificial intelligence (AI) and cloud computing, the increased demand for data processing has led to an increasing amount of heat generated. Currently, cooling activities account for up to 40% of total electricity consumption at data centers. Without a new solution, global energy consumption for cooling is forecast to double by 2030.

Compared to traditional air or liquid cooling, steam cooling can remove heat much more efficiently but consumes less energy, says Professor Renkun Chen, Faculty of Mechanical Engineering and Aerospace Engineering, Jacobs School of Engineering.

Previously, many efforts to apply a steam mechanism to cool high-power electronic devices were difficult because the holes in the cooling film were too small to clog or too large, causing unwanted boiling. This time, the research team used an optimal laying of the hollow film, helping to achieve high aerial performance without encountering the above limitations.

When tested under changing temperature conditions, this film has achieved record performance, handling heat waves of up to more than 800 watt/cm2 - one of the highest ever recorded for this type of cooling system. Technology also proves stability when operating continuously for many hours.

Although the initial results were very positive, Professor Chen said that the technology is still operating below the theoretical limit and the team is continuing to optimize performance. The next step is to integrate the film into the cooling panel prototype - a flat component directly attached to processing chips such asCPs or GPUs to distribute heat. At the same time, the research team is also implementing a startup company to commercialize this solution.