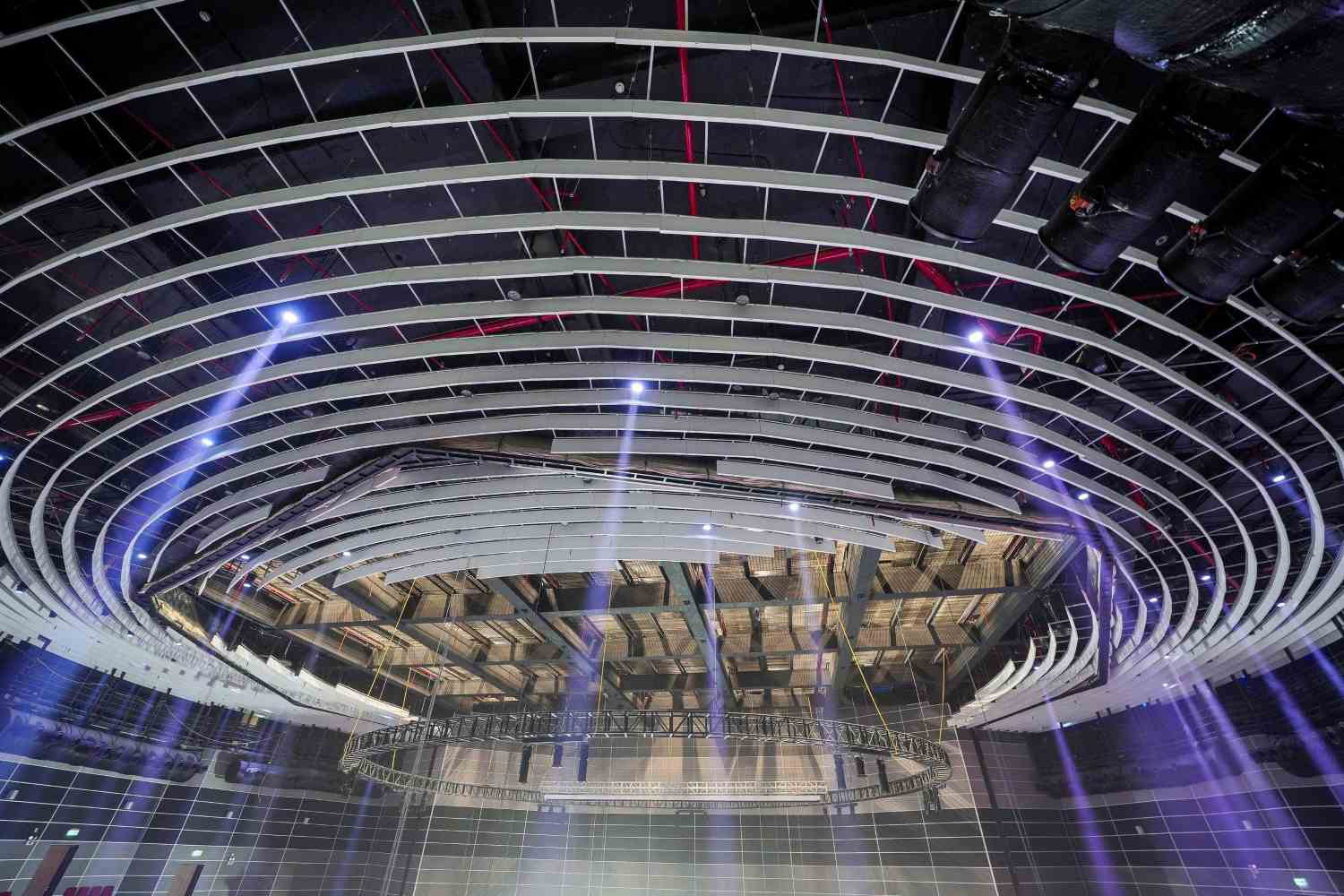

Recorded at the construction site on July 23, the main items of the central lobby with a capacity of 2,000 seats have been completed. Currently, the contractor focuses on installing sound, lighting, cleaning and organizing operations.

The highlight of the project is two stages - a mobile circle and a rectangle that can be flexibly combined into a multi-purpose stage to serve many different types of performances.

In particular, the modern spiral lifting system allows changing the performance context on both ground and underwater, creating unique effects, suitable for performances such as water puppetry, circus, and special art performances.

In addition to the large grandstand, the project also has many modern functional spaces. The 8th floor is a side practice and performance area with a 300-seat audience, equipped with specialized equipment such as swings, double stairs, conveyor belt in the air... to help artists practice complex performances.

Outside the project is a spacious campus with many trees, landscape water tanks and resting areas. The auxiliary areas include technical rooms, health stations, box offices, kitchens, warehouses and offices for the media.

In particular, behind the campus, there is also a specialized animal training area, over 1,000m2 wide, including a barn area, a practice space and a waiting yard behind the scenes, serving animal circus performances.

According to Mr. Chu Viet Han - Commander of Construction Corporation No. 1 (CC1 - contractor in charge of the main items including building structure, air conditioning system, ventilation, sound equipment, lighting, stage, ...), this is the project with the most complex techniques that the unit has ever constructed.

Notably, the composite floor system exceeding 53m at the 6th, 7th and 8th floors is a big challenge in terms of structure and accuracy. More than 1,000 tons of steel structure were used to create this floor system with a floor space of up to 24m high.

The construction process requires strict coordination between technical, mechanical and concrete teams. Every detail from moldboards, steel stones to support systems is strictly inspected and monitored to ensure absolute safety.

Unlike traditional works, the entire frame, wall and corridor here are constructed with reinforced concrete instead of bricks, to increase stability and long-term load-bearing capacity.

The sound system, lighting, power station, performance technology, chiller air conditioners, AHU... are all imported from abroad and installed according to international standards, requiring extremely accurate operation and adjustment.

The Phu Tho Multi-purpose Circus and Performance Project started construction in April 2023, with a total investment of nearly VND 1,400 billion from the Ho Chi Minh City budget.

The project is located on a land area of about 10,000m2, including 2 basements and 12 upper floors, with a total usable floor area of over 31,000m2, and a height of 57.5m.

This is a project with a designed life of up to 100 years, aiming for international performance standards with modern equipment and large scale organization.